Aluminium Heat Treatment: An Overview of Thermal profiling system

Aluminum heat treatment is a critical process that enhances the mechanical and physical properties of aluminum alloys, improving their strength, hardness, and durability. This involves carefully controlled heating and cooling to achieve the desired material characteristics. Among the most commonly used techniques are the T6 and T7 heat treatment processes, which involve key steps such as solution heat treatment, quenching, and aging.

T6 and T7 Heat Treatment Processes

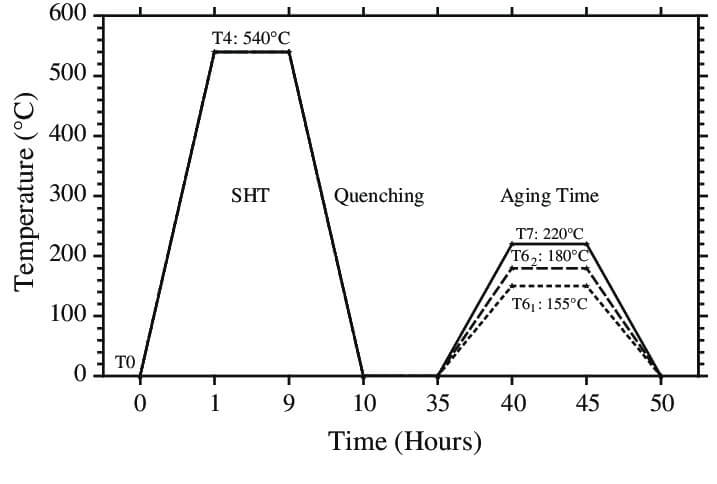

The T6 process consists of three main stages:

- Solution Heat Treatment: The aluminum alloy is heated to a high temperature (typically 480–620°C / 896–968°F) for 4–8 hours. This step dissolves the alloying elements into a solid solution, preparing the material for quenching.

- Quenching: After the solution heat treatment, the aluminum is rapidly cooled in water at 60–80°C (140–176°F) for 10–15 minutes. This rapid cooling locks the alloying elements in place, preventing unwanted precipitation and enhancing the mechanical properties of the metal.

- Aging: The quenched material is then reheated at a lower temperature (120–220°C / 248–356°F) for 6–8 hours. This allows the alloying elements to precipitate slowly, increasing the strength and hardness of the aluminum.

The T7 process is similar but includes an additional or modified aging step, making it more suitable for applications requiring higher thermal stability and resistance to stress and distortion.

The Importance of Quenching and Aging

Both quenching and aging play a crucial role in determining the final performance of aluminum alloys. If quenching is not done properly, it can lead to warping or residual stresses. On the other hand, correct aging ensures that the alloying elements precipitate correctly, resulting in improved strength, hardness, and overall material quality.

The Role of Thermal Profiling Systems in Heat Treatment

Precise temperature control is essential during heat treatment, especially during the critical quenching phase. Traditional methods often fail to provide complete data, leading to errors and inconsistencies. This is where the Thermal Profiling System from Tempsens makes a significant difference.

How Thermal Profiling Enhances Quenching and Aging

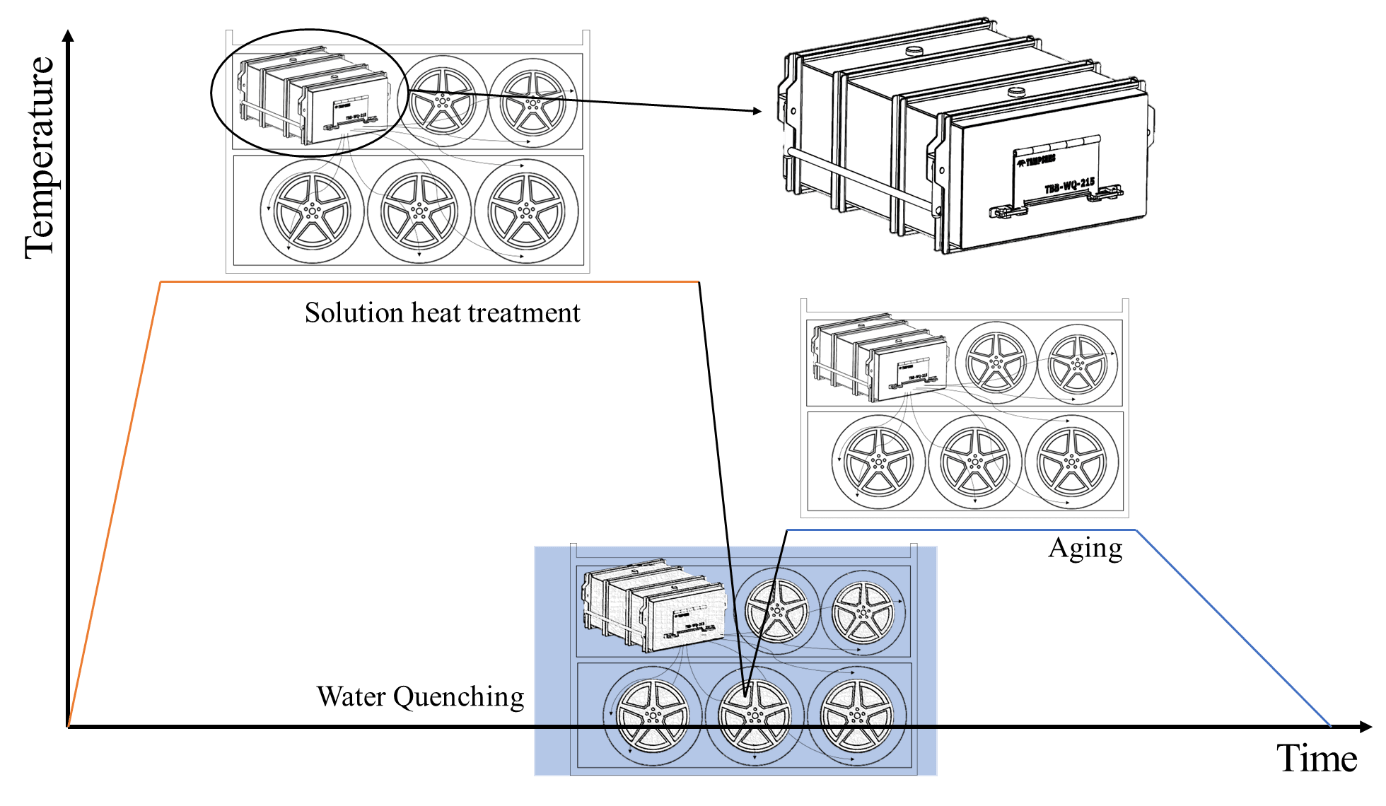

Tempsens Thermal Profiling System features a Thermal Barrier Box (TBB-WQ-215), a data logger, and thermocouples, all working together to monitor temperature in real-time throughout the T6 or T7 process.

- Thermal Barrier Box (TBB-WQ-215): It protects the data logger from extreme temperatures (up to 600°C / 1112°F) and sudden cooling during quenching.

Key Features:

- Â IP-67 Rating: Resistant to dust and water.

- Â Durable Construction: Built to withstand high temperatures and physical stress.

- Â Evaporative Cooling Technology: Keeps the data logger safe under extreme conditions.

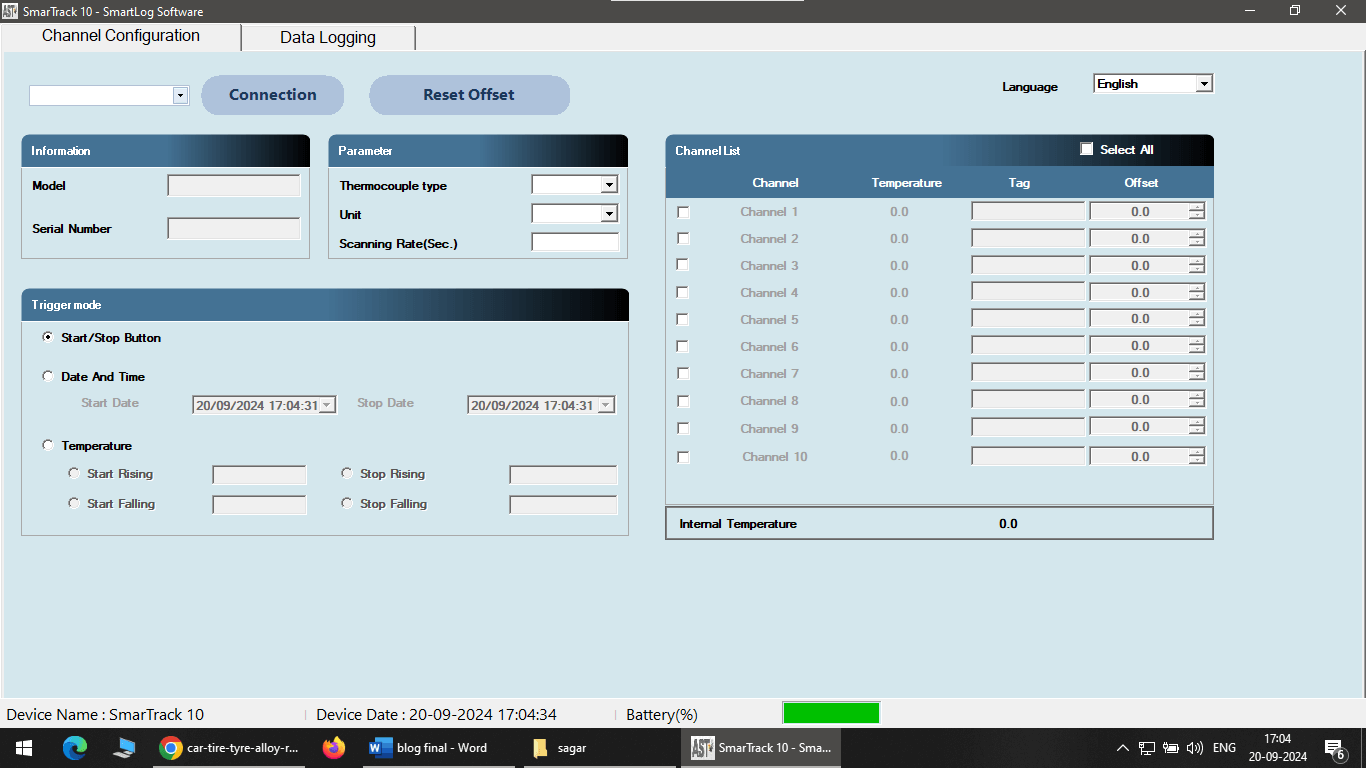

- Data Logger: The Tempsens SmarTrack 10 records precise temperature data, monitoring every stage of the heat treatment process.

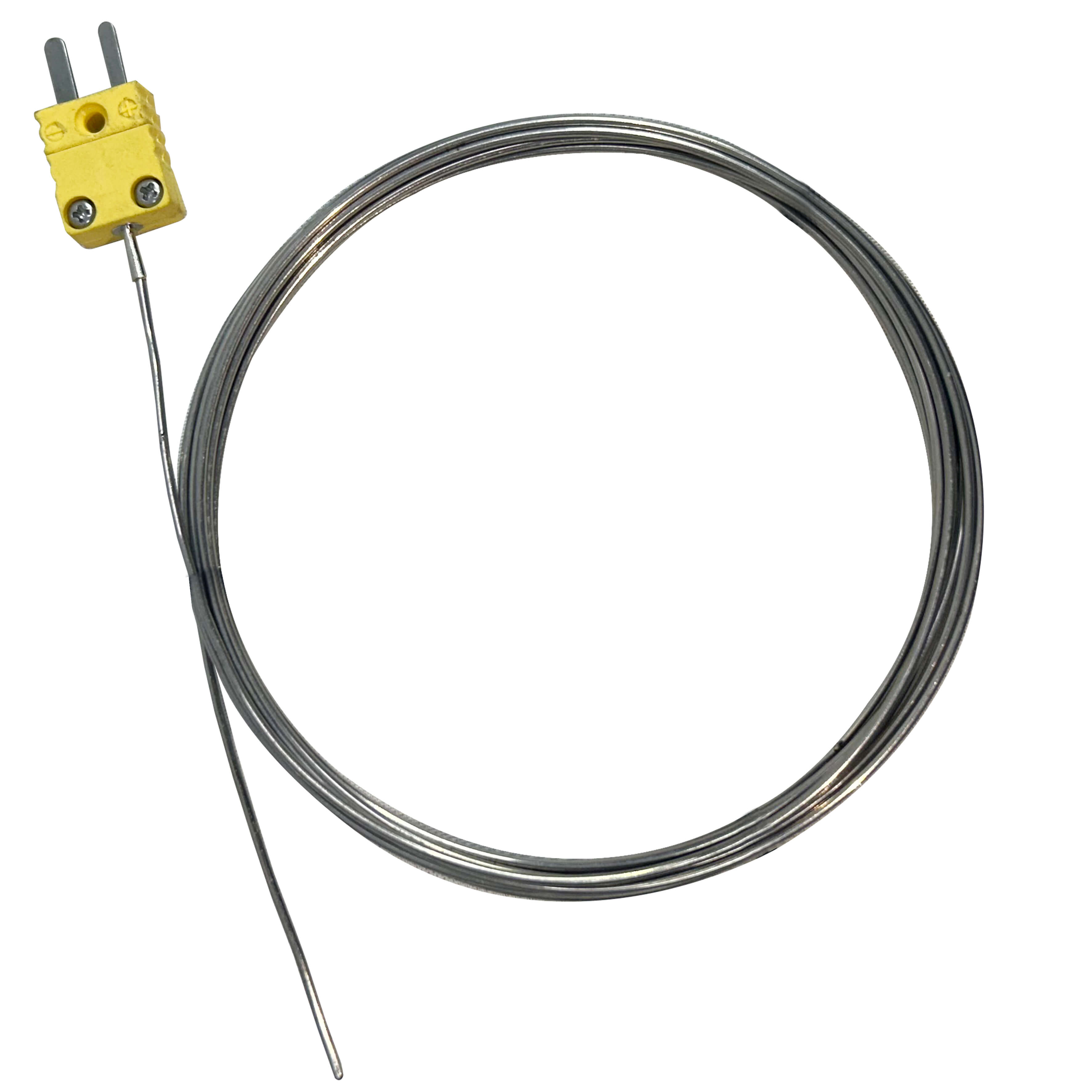

- Thermocouples: Positioned strategically to track temperatures across multiple points, ensuring accurate readings and preventing overheating or undercooling.

Benefits of Thermal Profiling

- Complete Temperature Data: Provides detailed profiles, allowing real-time adjustments to prevent issues like distortion or cracking.

- Process Validation: Ensures compliance with industry standards and validates the material’s mechanical properties for quality assurance.

- Improved Efficiency: Precise control leads to better product quality, less waste, and higher production efficiency.

Software for Data Processing and Temperature Analysis

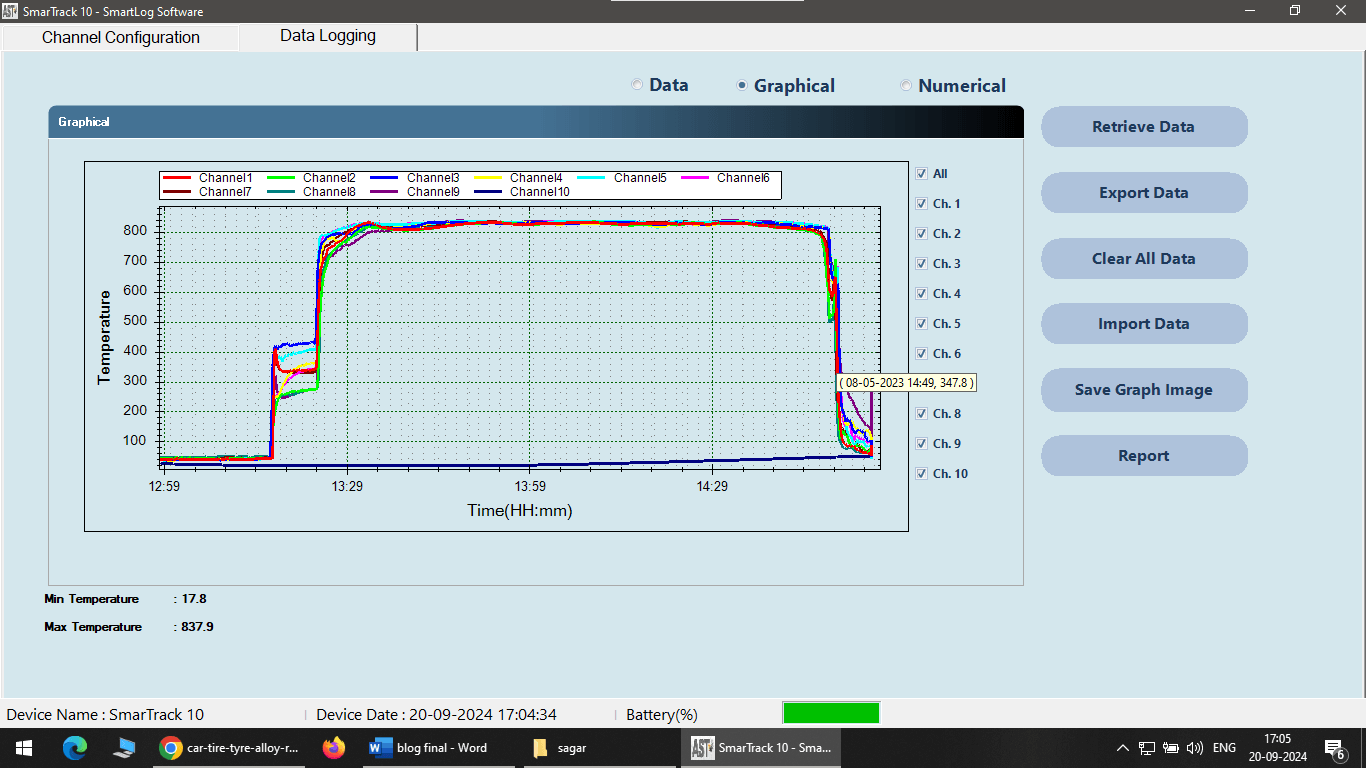

Tempsens also offers advanced Thermal Profiling Software that provides in-depth analysis of the entire heat treatment process.

- Real-Time Monitoring: Displays temperature data as it occurs, enabling immediate adjustments.

- Temperature Curve Visualization: Generates detailed graphs showing temperature changes over time.

- Temperature Difference Analysis: Identifies discrepancies that could cause defects.

- Process Optimization: Suggests improvements based on collected data for better efficiency and quality.

- User-Friendly Interface: Designed with intuitive visuals and reports for easy interpretation.

How Thermal Profiling Improves Quenching Accuracy

By monitoring the quench curve, manufacturers can ensure consistent cooling rates, reducing the risk of distortion, cracking, or residual stress. This precision helps achieve the desired mechanical properties—like hardness and tensile strength—reliably and consistently.

With components like the TBB-WQ-215 thermal barrier box, Tempsens Thermal Profiling System ensures accurate temperature control, minimizing defects and maximizing the quality of the final product. Whether you're performing T6 or T7 heat treatments, adopting thermal profiling can significantly enhance efficiency, validate your process, and improve material performance.

Inline Fuse,Inline Fuse Holder,Anl Fuse,In Line Fuse

Taishan Yuanjin Auto Parts CO., LTD , http://www.tsyuanjin.com