90 Degree Elbow Properties and Uses

Today, let's delve into the properties and applications of a 90-degree elbow. Understanding these aspects will ensure superior performance and precision in your projects.

Table of Contents

- Properties and Uses of 90 Degree Elbow

- Specifications of 90 Degree Elbow

- Dimensions and Size Chart for SS 90 Degree Elbow

- Weight Chart for Aluminum 90 Degree Elbow

- Materials Used for 90 Degree Elbow

- Pressure Ratings of Stainless Steel 90 Degree Elbow

- Dimensional Tolerance of Copper 90 Degree Elbow

- Angularity Tolerances for 90 Degree Elbow

- Chemical and Mechanical Properties of 4-inch 90 Degree Elbow

- Types of 90° Elbows

- Size Chart for SS 90 Degree Elbow

- Advantages of 90 Degree Elbow

Properties and Uses of 90 Degree Elbow

Properties:

- Bends the flow by 90 degrees

- Changes the direction of fluid flow at right angles

- Available in various sizes to match different pipe diameters and flow rates

- Pressure ratings vary based on material and design

- End types include threaded, welded, or flanged options

- Radius options: long radius or short radius

Applications:

Used to redirect pipeline directions

Helps manage the flow of liquids and gases

- Petroleum refineries

- Chemical industries

- Plumbing systems

- Power generation plants

- HVAC systems

90 Degree Elbow Manufacturing Standards

The ASME B16.9 standard is set by the American Society of Mechanical Engineers. It governs industrial buttweld fittings, specifying pressure ratings, size, material, marking, dimensions, surface finishes, fabrication methods, testing, and tolerances.

Specifications of 90 Degree Elbow

| Size Range of 90 Degree Elbow |

|

|---|---|

| Standards |

|

| Manufacturing Standards |

|

| Thickness of Stainless Steel 90 Degree Elbow |

|

| Coatings for 4 Inch 90 Degree Elbow |

|

| Type of Aluminum 90 Degree Elbow |

|

| Radius of Copper 90 Degree Elbow |

|

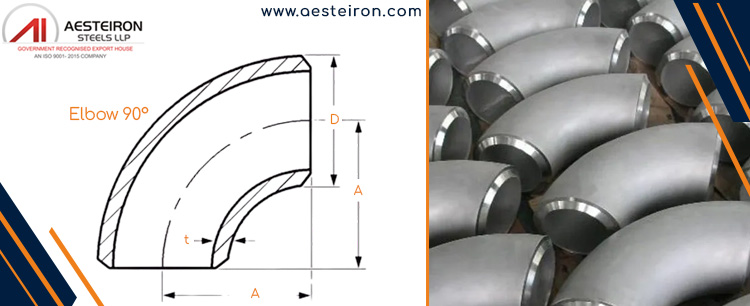

Reference Dimensions and Sizes for Stainless Steel 90 Degree Elbow

These elbows can be produced in various grades of stainless steel, especially grades 304 and 316. They offer excellent corrosion resistance, high strength, durability, aesthetic appeal, and minimal maintenance needs.

Below are some of the common sizes and dimensions of SS 90 degree elbows.

SS 90 Degree Elbow Dimensions and Size Chart

| Inch | D | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 3 1/2 | 4 | 5 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ND | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 90 | 100 | 125 | |

| MM | 21,34 | 26,67 | 33,40 | 42,16 | 48,26 | 60,32 | 73,02 | 88,90 | 101,60 | 114,30 | 141,30 | |

| Center to Center | O | 76,20 | 57,15 | 76,20 | 95,25 | 114,30 | 152,40 | 190,50 | 228,60 | 266,70 | 304,80 | 381,00 |

| Radius | A | 38,10 | 28,57 | 38,10 | 47,60 | 57,15 | 76,20 | 95,25 | 114,30 | 133,35 | 152,40 | 190,50 |

| Back to Face | K | 47,62 | 42,86 | 55,56 | 69,85 | 82,55 | 106,40 | 131,80 | 158,75 | 184,15 | 209,55 | 261,90 |

| Center to End | B | 15,87 | 11,11 | 22,22 | 25,40 | 28,57 | 34,92 | 44,45 | 50,80 | 57,15 | 63,50 | 79,38 |

| Inch | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | 28 | |

| ND | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 700 | |

| MM | 168,27 | 219,07 | 273,05 | 323,85 | 355,60 | 406,40 | 457,20 | 508,00 | 558,80 | 609,60 | 711,20 | |

| Center to Center | 457,20 | 609,60 | 762,00 | 914,40 | 1066,80 | 1219,20 | 1371,60 | 1524,00 | 1676,40 | 1828,80 | 2133,60 | |

| Radius | 228,60 | 304,80 | 381,00 | 457,20 | 533,40 | 609,60 | 685,80 | 762,00 | 838,20 | 914,40 | 1066,80 | |

| Back to Face | 312,70 | 414,30 | 517,50 | 619,10 | 711,20 | 812,80 | 914,40 | 1016,00 | 1117,60 | 1219,20 | 1422,40 | |

| Center to End | 95,25 | 127,00 | 158,75 | 190,50 | 222,25 | 254,00 | 285,74 | 317,50 | 342,90 | 381,00 | 441,90 |

Explore standards and weight chart of copper 90 degree elbow

Copper 90 degree elbows are versatile plumbing components designed for various piping and plumbing applications. They feature a 90-degree bend with long radius, providing smooth and seamless transitions in copper pipe installations.

The inherent properties of copper, such as its excellent corrosion resistance, ensure smooth water flow with minimal obstructions from rust. This makes it ideal for water distribution systems.

Aluminum 90 Degree Elbow Weight Chart

| NPS (Inch) | Â | Â | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 | 5 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LR 90 Deg Elbow | Sch. | 5S | 0.05 | 0.06 | 0.09 | 0.13 | 0.18 | 0.3 | 0.6 | 0.9 | 1.4 | 2.9 |

| Sch. | 10S | 0.06 | 0.07 | 0.15 | 0.2 | 0.3 | 0.5 | 0.85 | 1.3 | 2 | 3.6 | |

| Sch. | 40S | 0.08 | 0.09 | 0.18 | 0.25 | 0.4 | 0.7 | 1.35 | 2 | 4 | 6.5 | |

| Sch. | 80S | 0.1 | 0.11 | 0.2 | 0.35 | 0.5 | 0.9 | 1.8 | 2.9 | 5.9 | 9.7 | |

| SR 90 Deg Elbow | Sch. | 5S | 0.03 | 0.04 | 0.06 | 0.09 | 0.12 | 0.2 | 0.4 | 0.6 | 0.9 | 1.95 |

| Sch. | 10S | 0.04 | 0.05 | 0.1 | 0.13 | 0.2 | 0.33 | 0.6 | 0.9 | 1.35 | 2.4 | |

| Sch. | 40S | 0.05 | 0.06 | 0.12 | 0.17 | 0.27 | 0.47 | 0.9 | 1.35 | 2.65 | 4.35 | |

| Sch. | 80S | 0.07 | 0.07 | 0.13 | 0.12 | 0.33 | 0.6 | 1.2 | 1.9 | 3.9 | 6.5 | |

| NPS (Inch) | Â | Â | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 24 | |

| LR 90 Deg Elbow | Sch. | 5S | 4 | 7.4 | 13.6 | 23.4 | 29 | 41.3 | 51.8 | 73 | 122 | |

| Sch. | 10S | 5 | 10 | 16.8 | 27 | 35 | 47 | 59 | 85 | 140 | ||

| Sch. | 40S | 10.5 | 21.5 | 38.5 | 59 | 70 | 95 | 120 | 146 | 210 | ||

| Sch. | 80S | 16 | 33.5 | 52.5 | 79 | 94 | 125 | 158 | 194 | 282 | ||

| SR 90 Deg Elbow | Sch. | 5S | 2.7 | 4.9 | 9.1 | 15.6 | 19.3 | 27.5 | 34.5 | 49 | 82 | |

| Sch. | 10S | 3.35 | 6.7 | 11.2 | 18 | 23.5 | 31.5 | 39.5 | 57 | 94 | ||

| Sch. | 40S | 7 | 14.5 | 25.6 | 39.5 | 47 | 63.5 | 80 | 98 | 140 | ||

| Sch. | 80S | 10.5 | 22.5 | 35 | 53 | 63 | 84 | 105 | 129 | 188 |

90 degree pipe elbows are available in different materials like Stainless steel, Carbon steel, and Nickel alloys

Selecting the right material for a 90 degree pipe elbow is crucial because using the wrong material can lead to issues like erosion. Using a material not suited for the application can cause problems over time.

90 Deg Elbow Materials

| Material | Grades | Characteristics |

|---|---|---|

| Stainless Steel 90 deg elbow |

|

|

| Carbon Steel 90 degree elbow |

|

|

| Alloy Steel |

|

|

| Duplex / Super Duplex |

|

|

| Nickel Alloy |

|

|

View pressure rating and tolerance chart of ASME B16.9 90 deg elbow

Selecting the appropriate pressure rating and tolerance ensures that the application operates safely without leaks or damage. Below is a pressure rating and tolerance chart for two different materials, which can help prevent failures.

Stainless Steel 90 Degree Elbow Pressure Rating

| Temperature Ratings | (oF) | -20 to 150 | 500 | 250 | 200 | 300 | 400 | 350 | 450 | 550 | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (oC) | -29 to 66 | 260 | 121 | 93 | 149 | 204 | 177 | 232 | 288 | |||

| Pressure Class | 150 | 300 | – | 225 | 265 | 185 | – | 150 | – | – | ||

| 300 | 1/4 – 1 inch. | 2000 | 510 | 1575 | 1785 | 1360 | 935 | 1150 | 725 | 300 | ||

| 1 1/4 – 2 inch. | 1500 | 450 | 1200 | 1350 | 1050 | 750 | 900 | 600 | 300 | |||

| 2 1/2 – 3 inch. | 1000 | 385 | 825 | 910 | 735 | 560 | 650 | 475 | 300 | |||

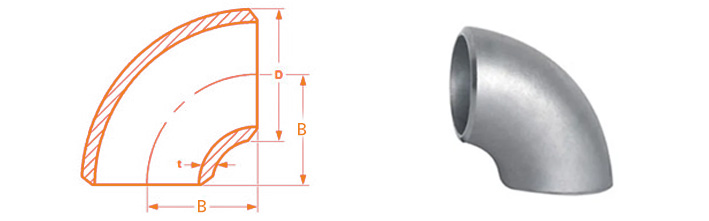

Copper 90 Degree Elbow Dimensional Tolerance

| Nominal Pipe Size | OD | At Bevel (D) | ID at End | Center to End LR (A/B) | Center to End 3D (A/B) | Nominal Pipe Size | OD | At Bevel (D) | ID at End | Center to End LR (A/B) | Center to End 3D (A/B) | Wall Thickness (t) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/2 to 2.1/2 | 1.6 | -0.8 | 0.8 | 2 | 3 | 10 to 18 | 4 | -3.2 | 3.2 | 2 | 3 | Not less than 87.5% of Nominal Wall Thickness | |

| 3 to 3.1/2 | 1.6 | 1.6 | 2 | 3 | 20 to 24 | 6.4 | -4.8 | 4.8 | 2 | 3 | |||

| 4 | 1.6 | 1.6 | 2 | 3 | 26 to 30 | 6.4 | -4.8 | 6.4 | -4.8 | 3 | 6 | ||

| 5 to 8 | 2.4 | -1.6 | 1.6 | 2 | 3 | 32 to 48 | 6.4 | -4.8 | 6.4 | -4.8 | 5 | 6 | |

90 Degree Elbow Angularity Tolerances

| ND | 1/2 a 4 | 5 a 8 | 10 a 12 | 14 a 16 | 18 a 24 | 26 a 30 | 32 a 42 | 44 a 48 | |

|---|---|---|---|---|---|---|---|---|---|

| Max off plane | P | 2 | 4 | 5 | 7 | 10 | 10 | 13 | 20 |

| Max off angle | Q | 1 | 2 | 3 | 3 | 4 | 5 | 5 | 5 |

Chemical and Mechanical Properties of 4-inch 90 Degree Elbow

| Materials | Chemical Properties | Mechanical Properties |

|---|---|---|

| Stainless Steel |

|

|

| Carbon Steel |

|

|

| PVC |

|

|

| CPVC (Chlorinated Polyvinyl Chloride) |

|

|

Types of 90° Elbows

Short Radius 90° Elbows (SR)

- Center-to-Face dimension

- 1.0 x Diameter

- Used in tight spaces where clearance is limitedSolid Epoxy Resin

Solid Epoxy Resin,Solids Epoxy Cyd-011,Epoxy Resin Cyd-014U,Sinopec Solid Epoxy Resin

Saint Petrochemicals Limited , https://www.saintpec.com