Stainless Steel Casting vs Forging

Below is a detailed comparison to help you decide whether casting or forging is more suitable for your specific application. This guide will provide insights into the key differences and advantages of each process, helping you make an informed decision.

Table of Contents

- Difference Between SS Forging vs Casting

- Stainless Steel Casting Process

- Reasons to Choose Forging and Casting Products

- SS 304 Castings Applications

- Advantages of SS Investment Casting

- Stainless Steel Cast Grades and Composition

- ASTM A351 CF8M Cast Fittings Testing Methods

- Types of Stainless Steel Pressure Die Casting Processes

- Methods Used for Stainless Steel 316 Casting

- SS Investment Casting vs Sand Casting

Key Differences Between Stainless Steel Forging and Casting

Choosing between forging and casting depends on several factors such as the complexity of the part, required strength, cost, and production volume. The table below highlights the main differences between the two processes:

| Features | Stainless Steel Casting | Stainless Steel Forging |

|---|---|---|

| Process | Metal is melted and poured into molds | Material is shaped while in a solid state using pressure |

| Size & Thickness | Limited by mold size and material properties | More flexible with a wide range of sizes |

| Shape Complexity | Can produce highly intricate parts | Better suited for simpler shapes |

| Tolerance | Less precise, may require post-processing | Offers tighter tolerances and better dimensional control |

| Strength | Lower mechanical strength compared to forged parts | Higher tensile and impact strength due to grain flow |

| Surface Finish | Typically rougher, requires finishing | Smoother finish with less need for additional processing |

| Cost | More cost-effective for small to medium runs | Higher initial costs due to tooling but better for large volumes |

| Internal Defects | More prone to porosity and shrinkage | Fewer internal defects and better material integrity |

| Applications | Used for complex components like valve bodies and pump housings | Preferred for structural and high-strength applications |

Understanding the Stainless Steel Casting and Forging Process

Whether you're looking for precision casting or strong forged components, understanding the processes involved can help you choose the best option for your needs. Here’s a breakdown of how stainless steel casting and forging work:

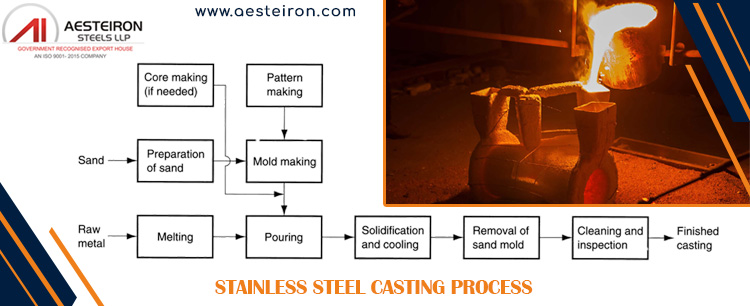

Stainless Steel Casting Process

The casting process involves creating a mold, melting the metal, and pouring it into the mold to form the desired shape. There are several types of casting methods, including sand casting, shell mold casting, investment casting, and ceramic mold casting. Each method has its own benefits and limitations depending on the application.

Top 5 Reasons to Choose Forging and Casting

Both forging and casting offer unique advantages that make them ideal for different applications. Below is a comparison of their key strengths:

Reasons to Choose Forging and Casting Products

| Forging | Casting |

|---|---|

|

|

Applications of Stainless Steel Forged and Cast Components

Stainless steel forgings and castings are widely used across various industries due to their excellent mechanical properties, corrosion resistance, and durability. Some common applications include:

SS 304 Castings Applications

- Oil and gas industry

- Construction and infrastructure

- Power generation

- Food and beverage processing

- Automotive and transportation

- Chemical and petrochemical sectors

- Medical and pharmaceutical equipment

- Kitchenware and cutlery

Advantages of Stainless Steel Investment Casting

Investment casting is a popular method for producing high-quality stainless steel components. It offers precision, smooth surfaces, and the ability to create complex geometries. Some key advantages include:

- Excellent heat resistance

- High durability and long service life

- Corrosion-resistant properties

- Environmentally friendly process

- Recyclable material

- Highly accurate dimensions

Technical Specifications and Grades of Stainless Steel Castings

Different grades of stainless steel are used in casting based on their chemical composition and mechanical properties. The following tables summarize some common grades and their specifications:

Stainless Steel Cast Grades and Composition

| Austenitic Stainless Steel Casting Grades | ||||||||

|---|---|---|---|---|---|---|---|---|

| 303 | 304 | 304L | 316 | 316L | 347 | 317 | ||

ASTM A351 CF8M Cast Fittings Testing Methods

- Mechanical Testing: Hardness, Tensile, Impact

- Visual Inspection

- Chemical Analysis

- Dimensional Check

- Ultrasonic and Radiographic Testing

Types of Stainless Steel Pressure Die Casting

Pressure die casting is a fast and efficient method for producing high-quality stainless steel components. It includes two main types: high-pressure and low-pressure casting. High-pressure casting is ideal for complex designs, while low-pressure casting is better suited for smaller, high-quality parts.

SS Investment Casting vs Sand Casting

When choosing between investment casting and sand casting, consider the level of detail, surface finish, and production volume. Investment casting offers higher precision and smoother finishes, making it ideal for aerospace, medical, and automotive applications. Sand casting, on the other hand, is more cost-effective for larger, less complex parts.

| Features | Stainless Steel Investment Casting | Sand Casting |

|---|---|---|

| Material | High-melting-point alloys (e.g., stainless steel) | Low to medium-melting-point metals (e.g., aluminum, zinc) |

| Surface Finish | Smooth and refined | Coarse and often requires post-processing |

| Dimensional Accuracy | High precision and tight tolerances | Lower precision and looser tolerances |

| Complexity | Capable of producing intricate shapes | Better for simpler designs |

| Cost | Higher initial cost but reusable tooling | Lower cost with single-use molds |

Wax Injection Machine,Servo Wax Injection Machine,Automatic Wax Injection Machine,Wax Injection Machine For Investment Casting

Dongying Fuhao Precision Casting Science & Technology Co.,Ltd , https://www.fh-cast.com