Stainless Steel Casting vs Forging

Below is a detailed comparison of casting and forging processes, helping you decide which method is best suited for your specific application. This guide covers key factors like material properties, cost, complexity, and performance to help you make an informed choice.

Table of contents

- Difference Between SS Forging vs Casting

- Stainless Steel Casting Process

- Reasons to Choose Forging or Casting

- SS 304 Castings Applications

- Advantages of SS Investment Casting

- Stainless Steel Cast Grades and Composition

- ASTM A351 CF8M Cast Fittings Testing Methods

- Types of Stainless Steel Pressure Die Casting Processes

- Methods Used for Stainless Steel 316 Casting

- SS Investment Casting vs Sand Casting

Key Differences Between Stainless Steel Forging and Casting

Choosing between forging and casting depends on several factors, including the required strength, shape complexity, cost, and production volume. The table below provides a clear comparison to help you understand the main differences between these two manufacturing methods.

Difference Between SS Forging vs Casting

| Features | Stainless Steel Casting | Stainless Steel Forging |

|---|---|---|

| Process | Casting involves melting metal and pouring it into a mold | Forging shapes metal while in a solid state using pressure |

| Size & Thickness | Limited by mold size and thickness capabilities | More flexible with a wide range of sizes |

| Shape Complexity | Can create complex and intricate shapes | Best for simpler, more straightforward designs |

| Tolerance | Less precise, not ideal for tight tolerances | High precision and better dimensional accuracy |

| Material Waste | Less waste due to precise molding | Higher waste from trimming and machining |

| Strength | Lower tensile and impact strength | Higher mechanical strength and durability |

| Surface Finish | Rougher finish, often requiring post-processing | Better surface finish with minimal finishing |

| Cost | More cost-effective for small to medium batches | Higher initial cost due to tooling and setup |

| Internal Defects | More prone to porosity and shrinkage | Fewer internal defects, higher integrity |

| Applications | Used for pump housings, valves, and other complex parts | Preferred for structural components and high-strength parts |

Understanding the Stainless Steel Casting and Forging Process

Both casting and forging have their unique advantages and are used across various industries. Below is a detailed explanation of the stainless steel casting process, along with a breakdown of how forging works.

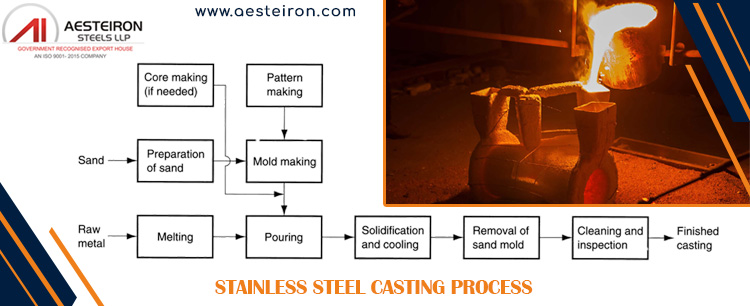

Stainless Steel Casting Process

Step 1: Pattern Making

Patterns can be made from wax, wood, plastic, or foam, depending on the casting method. These patterns are used to form the mold cavity.

- Wax patterns (used in investment casting)

- Wood or metal patterns (used in sand casting)

- Plastic and foam patterns (for low-cost prototyping)

Step 2: Casting Method

There are several casting techniques, each with its own advantages:

- Sand Casting: Uses sand molds, suitable for large and simple parts.

- Shell Mold Casting: Creates thin, accurate molds using resin-bonded sand.

- Investment Casting: Produces highly detailed parts with smooth finishes.

- Ceramic Mold Casting: Offers excellent surface quality and dimensional accuracy.

Step 3: Melting and Pouring

Metal is melted in a furnace and carefully poured into the prepared mold. This step must be done carefully to avoid damaging the mold or introducing defects.

Step 4: Finishing

After cooling, the casting is removed from the mold and undergoes cleaning, grinding, polishing, or machining to achieve the desired finish and dimensions.

Why Choose Forging or Casting?

Each process has its own strengths, and the right choice depends on your project's requirements. Here’s a quick overview of why you might choose one over the other.

Reasons to Choose Forging or Casting

| Forging | Casting |

|---|---|

|

|

Common Applications of Stainless Steel Forged and Cast Products

Stainless steel forged and cast products are widely used in various industries due to their strength, corrosion resistance, and versatility. Some of the most common applications include:

SS 304 Castings Applications

- Oil and gas industry

- Construction and architecture

- Power generation

- Food processing equipment

- Automotive and transportation

- Chemical and pharmaceutical sectors

- Medical devices

- Kitchenware and cutlery

Advantages of SS Investment Casting

- High heat resistance

- Excellent corrosion resistance

- Long-lasting and durable

- Environmentally friendly

- Recyclable material

- Resistant to wear and tear

- High-quality surface finish

Stainless Steel Cast Grades and Their Specifications

The following tables outline the chemical compositions and specifications of commonly used stainless steel casting grades. Understanding these will help you select the appropriate grade for your application.

Stainless Steel Cast Grades and Composition

| Austenitic Stainless Steel Casting Grades | ||||||||

|---|---|---|---|---|---|---|---|---|

| Â | Â | 303 | 304 | 304L | 316 | 316L | 347 | 317 |

| Silicon | Min-Max | 2.0 Max | 2.0 Max | 2.0 Max | 2.0 Max | 1.5 Max | 2 Max | 1.5 Max |

| Manganese | Min-Max | 1.5 Max | 1.5 Max | 1.5 Max | 1.5 Max | 1.5 Max | 1.5 Max | 1.5 Max |

| Carbon | Min-Max | 0.16 Max | 0.08 Max | 0.03 Max | 0.08 Max | 0.03 Max | 0.08 Max | 0.08 Max |

| Chromium | Min-Max | 18.0 -21.0 | 18.0-21.0 | 17.0-21.0 | 18.0-21.0 | 17.0-21.0 | 18.0-21.0 | 18.0-21.0 |

| Nickel | Min-Max | 9.0-12.0 | 8.0-11.0 | 8.0-12.0 | 9.0-12.0 | 9.0-13.0 | 9.0-12.0 | 9.0-13.0 |

| Phosphorus | Max | 0.04 | 0.04 | 0.04 | 0.04 | 0.04 | 0.04 | 0.04 |

| Molybdenum | Min-Max | 0.40-0.80 | Â | Â | 2.0-3.0 | 2.0-3.0 | Â | 3.0-4.0 |

| Sulfur | Min-Max | 0.20-0.40 | 0.04 Max | 0.04 Max | 0.04 Max | 0.04 Max | 0.04 Max | 0.04 Max |

| Ferritic Stainless Steel Casting Grades | |||||

|---|---|---|---|---|---|

| Â | Â | 409 | 442 | 446 | |

| Carbon | Max | 0.16 | 0.3 | 0.5 | |

| Silicon | Max | 2 | 1.5 | 1.5 | |

| Manganese | Max | 1.5 | 1 | 1 | |

| Nickel | Max | 0.5 | 2 | 4 | |

| Chromium | Min-Max | 10.5-11.75 | 18.0-22.0 | 26.0-30.0 | |

| Molybdenum | Max | Â | Â | Â | |

| Sulfur | Max | 0.045 | 0.04 | 0.04 | |

| Phosphorous Max | 0.045 | 0.04 | 0.04 | ||

| Copper | Max | Â | Â | ||

| Martensitic Stainless Steel Casting Grades | ||||||

|---|---|---|---|---|---|---|

| Â | 416 | 410 | 15-5 PH | 420 | 17-4 PH | |

| Silicon | Min-Max | 1.50 Max | 1.5 Max | 0.50-1.00 | 1.0 Max | 0.50-1.00 |

| Carbon | Min-Max | 0.15 Max | 0.05-0.15 | 0.05 Max | 0.15 Max | 0.06 Max |

| Manganese | Max | 1.25 | 1 | 0.6 | 1 | 0.7 |

| Nickel | Min-Max | 0.50 Max | 1.0 Max | 4.20-5.00 | Â | 3.60-4.60 |

| Chromium | Min-Max | 11.5-14.0 | 11.5-14.0 | 14.00-15.50 | 12.0-14.0 | 15.5-16.7 |

| Phosphorous | Max | 0.05 | 0.04 | 0.025 | 0.04 | 0.04 |

| Molybdenum | Min-Max | 0.50 Max | 0.5 Max | Â | Â | Â |

| Copper | Min-Max | 0.50 Max | 0.50 Max | 2.5-3.2 | Â | 2.8-3.5 |

| Sulfur | Min-Max | 0.15-0.35 | 0.04 Max | 0.025 Max | 0.03 Max | 0.03 Max |

| Duplex Stainless Steel Casting Grades | |||

|---|---|---|---|

| Â | ASTM A890 Grade 4A (CD3MN) | ASTM A890 Grade 1A (CD4MCu) | |

| Carbon | Max | 0.03 | 0.04 |

| Silicon | Max | 1 | 1 |

| Molybdenum | Min-Max | 2.5-3.5 | 1.75-2.25 |

| Chromium | Min-Max | 21.0-23.0 | 24.5-26.5 |

| Manganese | Max | 1.5 | 1 |

| Nickel | Min-Max | 4.5- 6.5 | 4.75-6.00 |

| Phosphorous Max | 0.04 | 0.04 | |

| Copper | Min-Max | 1.00 Max | 2.75-3.25 |

| Sulfur | Max | 0.02 | 0.04 |

Testing Methods for Stainless Steel Precision Castings

To ensure the quality and reliability of stainless steel castings, several testing methods are performed. These tests help identify any defects and ensure that the final product meets the required standards.

ASTM A351 CF8M Cast Fittings Testing Methods

- Mechanical Testing:

- Hardness Test

- Tensile Test

- Impact Test

- Visual Inspection

- Chemical Composition Analysis

- Dimensional Inspection

- Ultrasonic Testing

- Radiographic Testing

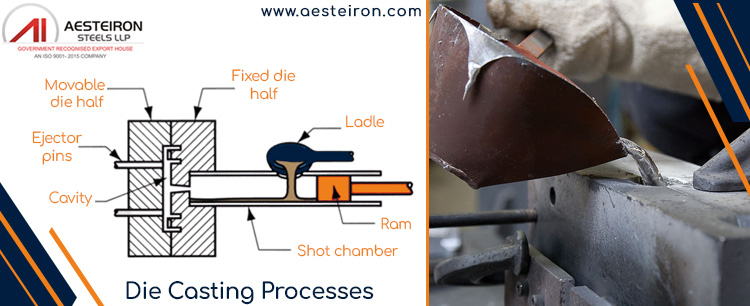

Types of Stainless Steel Pressure Die Casting Processes

Pressure die casting is typically divided into two main types:

High Pressure Die Casting

- Uses a cold or hot chamber system to inject molten metal under high pressure

- Commonly used for aluminum, zinc, and other non-ferrous metals

- Produces parts with high dimensional accuracy and good surface finish

- High injection speed (up to 1100 bar)

- Used for mass production of complex parts

Low Pressure Die Casting

- Uses lower pressure for filling the mold

- More suitable for metals with lower melting points

- Results in fewer defects and better microstructure

- Not typically used for stainless steel due to its high melting point

Methods Used for Stainless Steel 316 Casting

| Methods | Details |

|---|---|

| Investment Casting | Uses wax or foam patterns to create highly detailed parts |

| Sand Casting | Utilizes sand molds for creating complex and precise components |

| Continuous Casting | Used in industrial settings to produce long, uniform sections |

| Pressure Die Casting | Produces near-net-shape parts with high precision |

| Centrifugal Casting | Uses centrifugal force to fill the mold |

| Lost Wax Casting | Eliminates the need for a separate pattern after casting |

SS Investment Casting vs Sand Casting

| Features | Stainless Steel Investment Casting | Sand Casting |

|---|---|---|

| Material | High melting point alloys (e.g., stainless steel) | Low to medium-melting-point metals (e.g., aluminum, zinc) |

| Surface Finish | Smooth and refined | Coarse, requires additional finishing |

| Mechanical Properties | Excellent strength and durability | Good but less precise |

| Dimensional Accuracy | High precision and tight tolerances | Lower precision |

| Complexity | Can produce highly intricate shapes | Best for simpler, basic shapes |

| Tooling Cost | Expensive but reusable | Relatively inexpensive and disposable |

| Cost | Higher initial cost, but cost-effective for high-precision parts | Lower cost, ideal for larger volumes |

| Application | Aerospace, medical, automotive, and high-tech industries | General manufacturing, automotive, and industrial parts |

Wax Injection Machine,Servo Wax Injection Machine,Automatic Wax Injection Machine,Wax Injection Machine For Investment Casting

Dongying Fuhao Precision Casting Science & Technology Co.,Ltd , https://www.fh-cast.com