I have to tell you before you have environmental safety issues with your ultrafine mineral powder!

In recent years, with the development of environmental medicine and environmental mineralogy, the potential safety problems of mineral powders to the environment and organisms have received more and more attention.

Studies have shown that most mineral powders are biologically toxic, especially for submicron and nanoscale powders.

(Click on the picture to see: ultra-fine mineral powder material is applied to resolve PS:!! Please do not tell non-metallic mineral products Jing money, but you did not do it)

Ultrafine mineral powder materials will enter the environment in a new form during production and use, even after being discarded. Their unique structure and special composition are easily absorbed or converted in the environment and released. Free radicals, heavy metals and other highly active and toxic and harmful substances, thereby destroying the balance of the environment and the biological system.

The manifestation of the toxicity of ultrafine mineral powder:

Some large mineral particles show toxicity due to their release of toxic substances;

Some mineral powders are toxic due to their characteristic ultrafine effects or directly attack specific parts of cells and microbial individuals;

Some mineral ultrafine powders are very toxic due to their strong sorption and are easily absorbed by other organisms.

According to their different targets, the environmental safety of ultrafine mineral powders is mainly divided into three categories: epidemiological investigation, microbial activity and cytotoxicity.

ã€1】

Mineral powder epidemiological survey

The ultra-fine mineral powder can pass through the whole process of the human respiratory system, and will deposit in the respiratory tract after entering the human body. The powder particles themselves and their dissolution cause the dysfunction of the body tissues, which leads to the occurrence of lesions.

In China, the case of pneumoconiosis, a statutory occupational disease caused by productive powders, has accumulated more than 600,000 cases of pneumoconiosis. In recent years, the number of new pneumoconiosis cases has been around 10,000 per year, and there is an upward trend.

In addition, epidemiological survey results show that the long-term exposure to a large concentration of powder environment, the incidence of cancer in the respiratory system is significantly increased.

Asbestos powder is directly related to the occurrence of mesothelioma, fibrosarcoma, adenocarcinoma and squamous cell carcinoma. The hazards of fibrous zeolites such as erionite have attracted considerable attention. Gem processing workers have multiple diseases such as tuberculosis and emphysema.

(Maolin)

In the construction industry, the concentration of respirable concrete powder is much higher than the prescribed safety bottom line, and it is very difficult to prevent silicosis. Long-term exposure to high concentrations of cement powder results in a decrease in maximum vital capacity (FVC).

Particles of 10 μm diameter are usually deposited in the upper respiratory tract, 5 μm in diameter can enter the deep part of the respiratory tract, and below 2 μm can be 100% deep into the bronchioles and alveoli. Continuous exposure to different concentrations of olivine, amphibole, tremolite, and silica particles of 8-30 μm in length and less than 0.25 μm in diameter can cause pleural tumors.

Ultrafine mineral powder can directly enter the alveoli, and because of its strong activity and easy diffusion, it is more harmful to human health. Therefore, it is necessary to control the concentration of powder particles in the processing workshop during the processing of mineral powder, and do well in the process of use. Protective measures.

Further, a portion of mineral drugs and improper use can lead to damage of the formulation and acute renal failure, renal toxicity produce clinical lesions, such as those containing arsenic, mercury, lead and copper are minerals.

ã€2】

Study on Microbial Activity of Ultrafine Mineral Powders

Adsorption (adhesion) between microorganisms and minerals is the basis for the interaction between the two. The ultrafine mineral powder particles are similar in size to the general microbes (micron and submicron), so the energy exchange and material exchange between them are extremely active.

During the process of particle interface/cell membrane, the ultrafine mineral particles cause puncture, inlay, and wall breaking behavior of microorganisms, and the changes of bacterial morphology, enzymes, and metabolites, and the toxicity of bacterial components and metabolites. Physiological response to immune damage caused by bacterial components.

On the other hand, microbes have powdering and erosive effects on mineral powders, causing mineralogical responses such as surface morphology, groups and charge changes, and the metabolites released by microorganisms accelerate the dissolution of mineral particles and produce more harmful components. It will stimulate the variation of the ability of the bacteria to resist the phagocytosis and lyase of the capsule. Recently, researchers have defined it as "near-size effect".

Some research results show that the biosorption rate of minerals such as calcite , quartz and cassiterite decreases with the increase of pH value, and the microorganisms adjust their functions to adapt to the growth conditions and environment, and can change the surface of minerals. Adsorption capacity, the adsorption capacity of heavy metals and toxic and harmful organic matter is significantly improved.

Sub-micron and nano-scale mineral powders have an effect on the normal physiological activities of microorganisms on the surface of human skin and in vivo, thus changing the stability of the human defense system and causing the occurrence of lesions.

A certain concentration of brucite below 10μm can promote the growth and metabolism of E. coli, increase its product content and enzyme activity, thereby increasing the number of E. coli.

Mineral powders with high calcium or magnesium ions can promote the growth and metabolism of three normal bacteria (S. epidermidis, Streptococcus mutans and Escherichia coli).

[3]

Cytotoxicity of ultrafine mineral powder

The toxicity of ultrafine mineral particles to animal tissues is mainly manifested in the toxicity to cells, which causes pathological damage through damage to cells.

Experiments have shown that mineral powders containing free silica have toxic effects on cells, such as nano-SiO2, sandstone ore, cement powder, and the like.

Fibrous mineral powders are more cytotoxic than granular minerals, such as asbestos, fibrous brucite, and rayon.

The acicular mineral powder can puncture the cell membrane, causing the cell to rupture and die.

The interaction of ultrafine mineral particles with cells produces reactive oxygen species such as hydroxyl radicals (•OH). The reactive oxygen species destroy the stability of the cell system by destroying the cell membrane and affecting the normal expression of the gene, causing the cells to inactivate or cause pathological changes. Mineral particles that are engulfed by cells can accumulate inside the cells for a long time. If the dissolution rate is lower than the accumulation rate, the cells are mineralized, or fibrotic, or ruptured and died after a long time.

The main component of atmospheric respirable particulate matter (PM2.5) is minerals. After the adsorption of heavy metals and harmful organic matter by ultrafine particles of minerals, the cytotoxicity is obviously enhanced and the harm to the human body is greater. This is becoming a research hotspot in the field of environmental protection at home and abroad. Therefore, control and pollution control of atmospheric particulate matter, especially the concentration of respirable particulate matter, is particularly important.

[4]

How to eliminate or reduce the environmental toxicity of ultrafine mineral powder?

With the continuous development of industrial modernization and the increasing demand for high-tech products, the application prospects of ultra-fine mineral powder materials are very broad.

However, ultrafine mineral particles have environmental and biological safety characteristics, which will hinder the promotion and use of such materials, especially in today's society that advocates the concept of scientific development and sustainable development. How to develop environmentally friendly ultra-fine mineral powder materials is a new technology with great development potential and great development space.

The environmental toxicity of mineral powder particles is mainly caused by free radicals and ions to be dissolved, so it can be eliminated or reduced, such as surface modification, surface acid-base treatment or development of specific mineral powder substitute materials. .

The main material of the product is carbon steel.

The handle of the product is telescopic.

The design of the handle is hard and light.

Packing: Ratchet Cable Cutterpacked by carton or as your request.

Applications: Electric power industry,Mommunication industry,Mhip-building industry,Metaluraical industry.

Features:

1. Cutting easily with forging blade and long lifetime

2. Not for cutting steel or steel wire

3. With safety lock

4. Cutting Range:240mm² max.

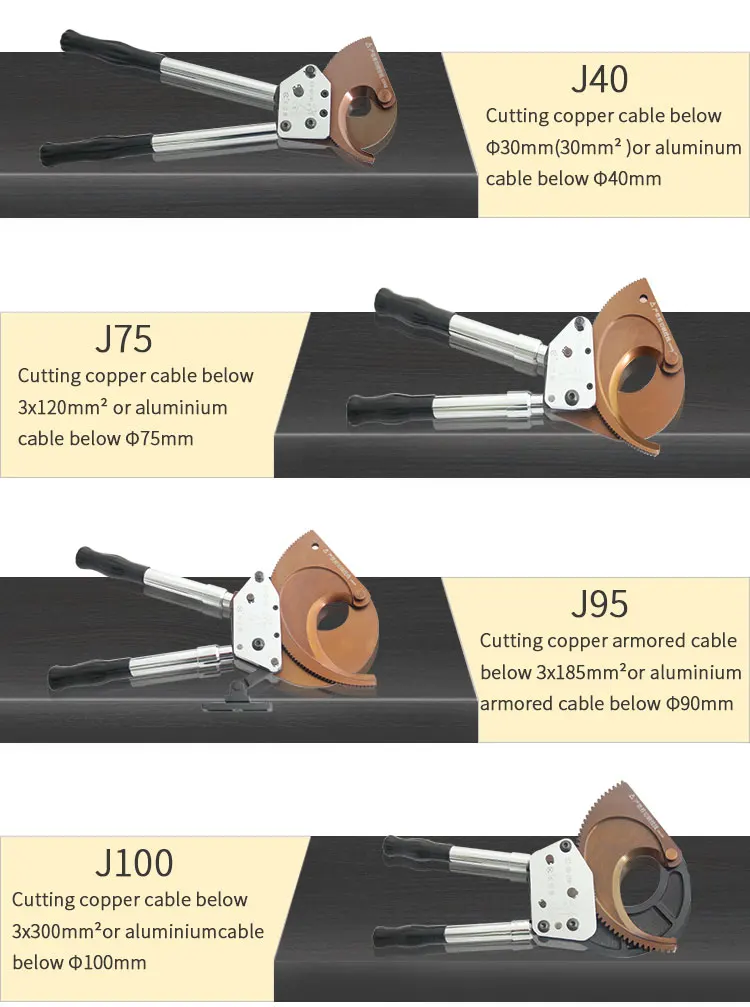

Ratchet Cable Cutter Different specifications as below:

|

Ratchet cable cutter |

||

|

Model |

Size |

Weight |

|

J12 |

345(514)*125*46mm |

1.95kg |

|

J30 |

405(514)*160*64mm |

3.6kg |

|

J13 |

345(514)*125*46mm |

1.95kg |

|

J25 |

745*135*50mm |

3.45kg |

|

J50 |

400(570)*158*52mm |

3.2kg |

|

J40 |

260*100*35mm |

1.15kg |

|

J40A |

245*135*42mm |

1.05kg |

|

J40B |

250*95*30mm |

0.65kg |

|

J75 |

420*205*50mm |

3.6kg |

|

J95 |

818*265*50mm |

5.43kg |

|

J100 |

490*270*50mm |

6.4kg |

|

J130 |

500*300*50mm |

8.1kg |

|

J160 |

500*300*50mm |

8.11kg |

Ratchet Cable Cutter Details:

Ratchet Cable Cutter

Ratchet Cable Cutter,Cable Cutters,Ratchet Cutters,Ratchet Wire Cutters

Hebei Long Zhuo Trade Co., Ltd. , https://www.hblongzhuo.com