Eliminating downtime for a train station roof inspection with Elios drones

Eliminating Downtime for a Train Station Roof Inspection with Elios Drones

When it comes to maintaining critical infrastructure like train stations, avoiding disruptions is key. In the Netherlands, the pressure to keep rail services running smoothly led an inspection team to seek innovative solutions. Their answer came in the form of the Elios 3 drone, which allowed them to inspect the roof of a busy train station without interrupting daily operations.

Key Benefits at a Glance

|

Accessibility Traditional methods required scaffolding, which would have halted train activity for weeks. Using the Elios 3, inspectors could navigate around the station's intricate architecture safely and efficiently. |

No Downtime By scheduling flights at night, the team ensured minimal impact on passenger schedules. Unlike previous methods requiring train shutdowns, this approach kept trains running smoothly throughout the inspection process. |

|

Safety The complex structure of the station posed significant risks to human inspectors. The Elios 3 eliminated these dangers by allowing remote data collection. |

Efficiency Data collection was completed in just two flights, reducing both time and costs compared to traditional methods. |

Public transportation delays are never ideal, causing frustration among commuters and potential logistical nightmares for freight trains. Ensuring the structural integrity of train stations is essential for smooth operations. However, inspecting parts like the roof while trains are active presents unique challenges. How did this team overcome these obstacles?

Could the Elios 3 handle the task of inspecting a train station roof?

Customer Requirements: Inspecting a Train Station Roof

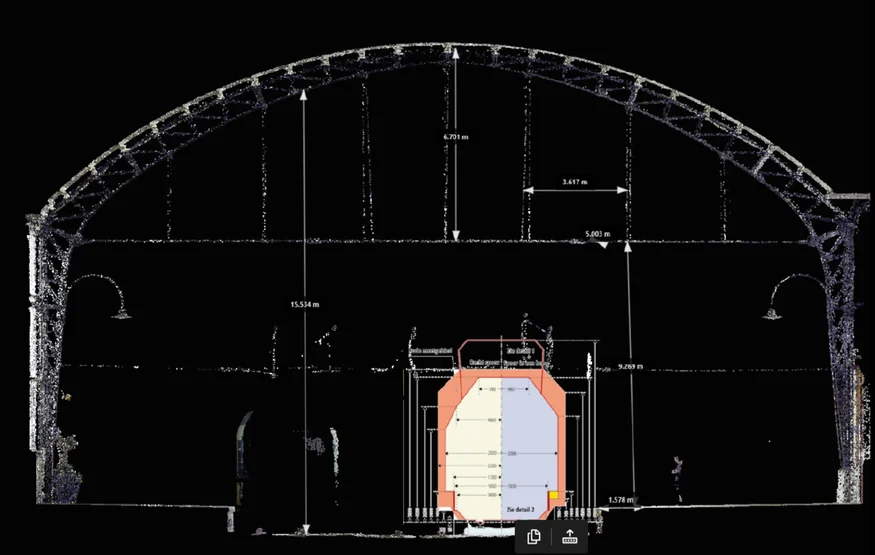

Vortex Hardware & Maintenance BV, a leading drone and robotics provider in the Netherlands, partnered with NS Stations to address various maintenance challenges across the country’s railway infrastructure. From small regional hubs to major urban terminals, each station presented its own set of complexities. One particular station, constructed in the early 1900s, raised concerns about its aging metal beams supporting the roof. Gaps between the beams and the roof needed thorough examination, yet direct access was impractical without extensive scaffolding, which would disrupt rail services. Without actionable data, maintenance decisions relied heavily on worst-case assumptions—clearly not ideal.

The Elios 3 emerged as the perfect solution. Its ability to collect high-quality data remotely while minimizing risk made it indispensable for this mission-critical task.

Implementation: Leveraging the Elios 3 for Data Collection

Remco Bunder and Sep Schetters of NS Stations had collaborated with Ruben of Vortex on similar projects before, so they trusted the Elios 3’s capabilities. Previously, the Elios 2 had successfully inspected a pedestrian bridge, capturing detailed images from challenging angles. Inspired by those results, Ruben, Remco, and Sep believed the Elios 3 could deliver even better insights for this project.

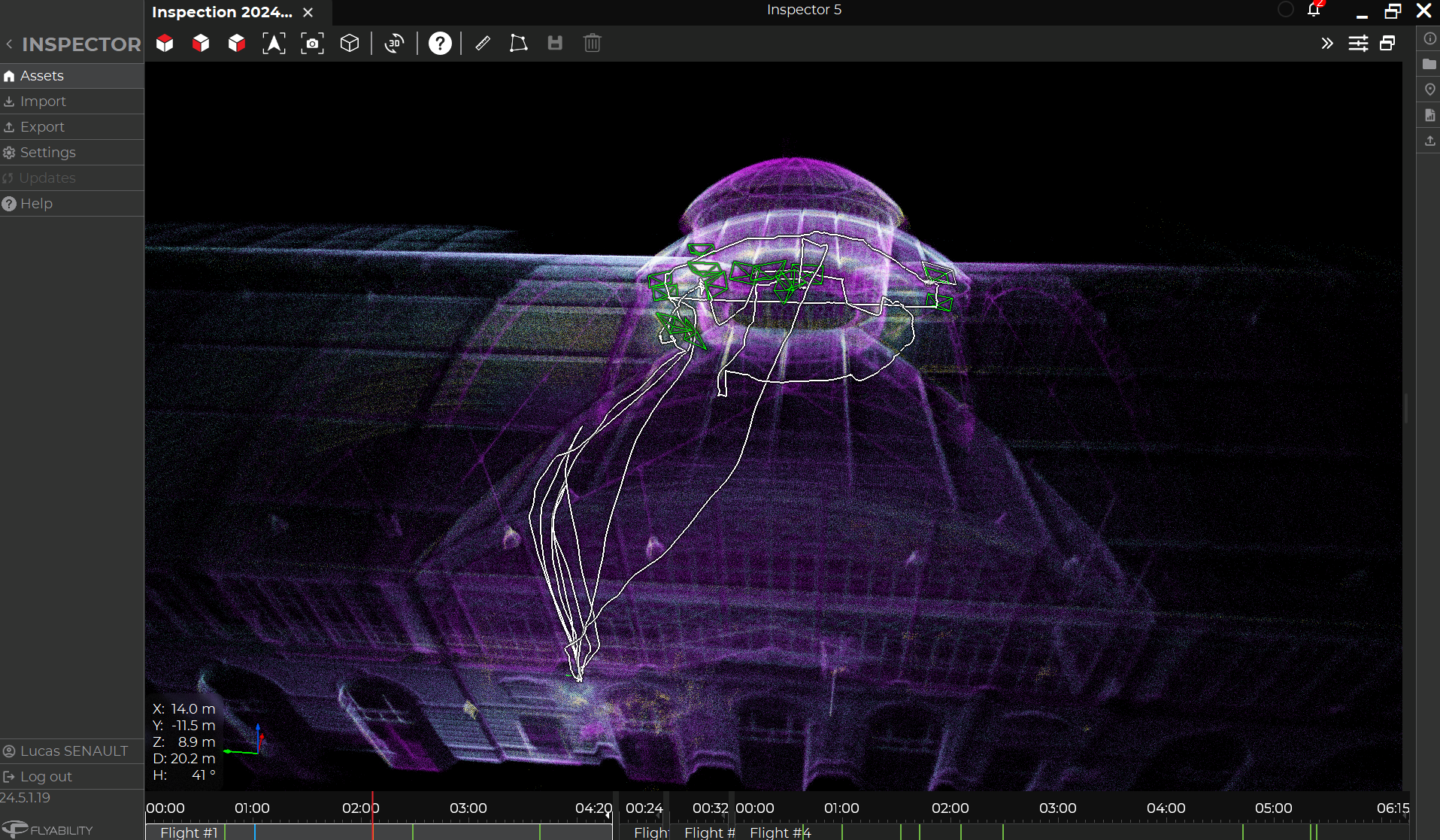

A LiDAR scan captured intricate details of the station, helping plan safe drone routes.

For this western Dutch station, Ruben and his team planned a meticulous strategy. Combining ground-based LiDAR scans with aerial data collection ensured compliance with stringent European aviation regulations limiting drone usage near populated areas and trains. To avoid any interference with operational trains, they scheduled flights late at night when fewer trains ran and fewer people were present. Additionally, coordinating with local air traffic control added another layer of safety during their operations.

Outcomes: Nighttime Flights Deliver Results

With precise measurements obtained via LiDAR technology, Ruben first sent out an Elios 2 drone for preliminary scouting. After analyzing initial footage, he returned with the Elios 3 to execute preplanned flight paths targeting specific zones of concern while also conducting broader surveys. A construction advisor assisted onsite by highlighting key points of interest. Coordinating closely with station personnel, Ruben maintained constant vigilance over train schedules to ensure flights never coincided with active trains.

Spot the Elios 3 mid-flight!

Advantages of Using the Elios 3 for Infrastructure Inspections

In the past, such inspections required complete shutdowns lasting several weeks, involving costly scaffolding setups and mandatory power disconnections from overhead lines. Such procedures often occurred infrequently, leaving little room for proactive maintenance planning. By contrast, the Elios 3 enabled targeted inspections conducted swiftly and safely, providing invaluable real-time data for future upkeep efforts.

Laser scanning revealed structural details inaccessible by humans.

Risks associated with traditional inspections were drastically reduced thanks to the Elios 3. Electrocution hazards from live wires and collision risks from moving trains disappeared entirely. Furthermore, its robust lighting system, delivering 16,000 lumens, ensured excellent visibility even during nocturnal missions. Flexibility and adaptability made it the ideal choice for navigating tight spaces and complex environments.

Future Applications of the Elios 3 in Rail Infrastructure

Already renowned for pioneering drone-based inspections nationwide, both Vortex and NS Stations found new opportunities with the Elios 3. Managers gained unprecedented clarity into their facilities’ conditions, enabling more informed decision-making processes. Safety remained paramount throughout the project, protecting workers and passengers alike.

When full renovations become unavoidable, they typically require extensive planning cycles spanning multiple years. Thanks to the Elios 3, however, only necessary repairs were carried out this time, sparing significant operational disruptions. Financial savings reached millions of euros, alongside substantial time reductions achieved through accurate pre-maintenance data acquisition. ProRail, the client responsible for overseeing this project, praised the innovation, emphasizing enhanced flexibility and efficiency brought about by adopting drone technologies.

Weeks of labor saved, no service interruptions realized!

Station administrators now possess comprehensive 3D models accessible via computer screens, empowering them to adopt proactive approaches toward asset management rather than adhering strictly to predefined maintenance calendars. Discover further possibilities offered by the Elios 3 today!

Pickleball Set Top,Top Pickleball Sets,Control Pickleball Paddles,Pickleball Set

Nantong Zhongyi Electronic Technology Co., Ltd. , https://www.apl-pickleball.com