Eliminating downtime for a train station roof inspection with Elios drones

Eliminating Downtime for a Train Station Roof Inspection Using Elios Drones

With the need to keep rail activity uninterrupted, an inspection team in the Netherlands decided to use the Elios 3 drone for assessing the roof of a busy train station. This move was crucial to avoid any disruptions in rail services, which can lead to significant delays and inconvenience for commuters.

Key Benefits at a Glance

|

Accessibility Given the unique architecture of the station, it was impossible to access the roof safely for inspection purposes. Traditional methods would have required shutting down three train lines and deactivating the overhead power lines, which would take months of planning. Instead, the Elios 3 drone was flown around the structure during the night to collect essential data. |

No Service Disruptions By conducting the inspection at night and leveraging the capabilities of the Elios 3, the NS Stations team managed to keep trains running smoothly. This ensured no changes to public transport schedules due to the inspection. Previously, working on the roof would necessitate closing multiple lines and ensuring the catenary was voltage-free. |

|

Safety Accessing the roof manually posed significant risks due to the structural complexity and the presence of live electrical systems. The Elios 3 offered a secure way to gather vital data without endangering personnel or inconveniencing passengers. Â |

Efficiency Data collection was completed swiftly during the night when the station was less crowded. The entire operation was wrapped up in just two flight sessions, saving both time and resources. Â |

Delays in public transportation can be frustrating for everyone involved. They disrupt travel plans, causing stress for commuters, and can even impact supply chains if freight trains are delayed. Therefore, maintaining trains and related infrastructure, such as tracks, signaling systems, and stations, is crucial to ensure smooth operations.

Inspecting specific parts of a station, like the roof, becomes challenging when trains are constantly moving along the platforms. How do you address this issue? The Elios 3 drone provides an innovative solution.

The Elios 3 has already inspected railway bridges - but what about train station roofs?

Customer Requirements: Inspecting the Roof of a Train Station

Vortex Hardware & Maintenance BV, a Dutch drone and robotics specialist and Flyability partner, has collaborated with NS Stations on numerous maintenance projects at various railway locations across the country. They have successfully executed several proof-of-concept initiatives focusing on inspecting railway station infrastructure. These stations vary in size, age, and design.

At one particular station, concerns arose regarding the metal beams in the roof. Built in the early 1900s, the station faced challenges in inspecting the roofing structure. The space between the metal load-bearing components and the roof itself needed thorough analysis, but accessing these areas safely was impossible without setting up scaffolding, which would disrupt rail activity. Without proper inspection data, maintenance work would rely on worst-case scenario assumptions. To address this, the Elios 3 drone presented a viable solution for safely collecting data without interrupting station operations.

Solution: Inspecting a Train Station with the Elios 3

Remco Bunder and Sep Schetters of NS Stations had previously worked with Ruben from Vortex, so they were confident in using an Elios drone for this project. The Elios 2 had already proven effective in inspecting a pedestrian bridge with two technical rooms and the interior of the bridge via manhole access. Despite the bridge's complex structure and difficult access points, the Elios drone made the task manageable.

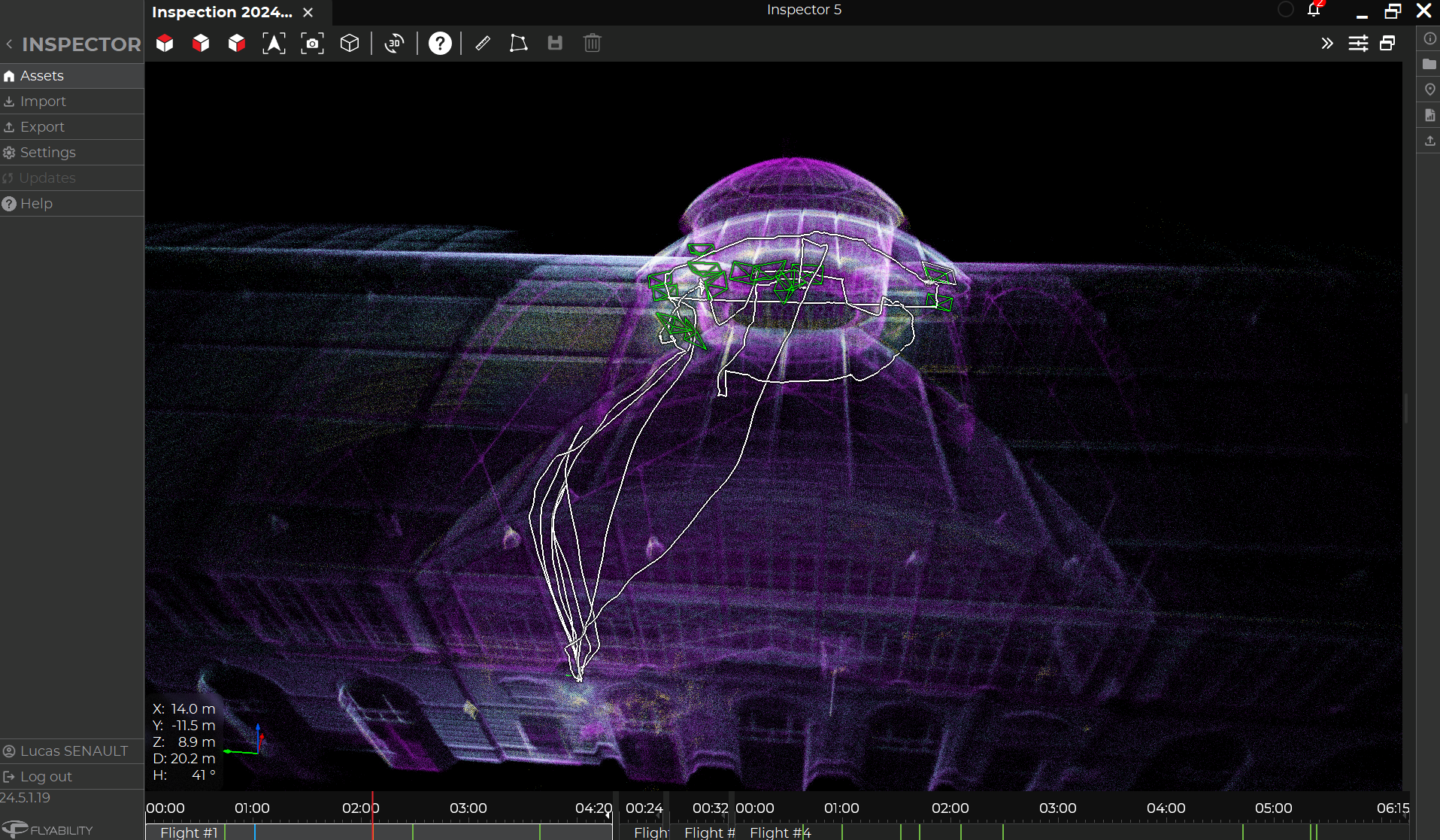

The LiDAR scan of the train station with the Elios 3 captured intricate details, including this protruding element in the roof

For this station located in the western part of the Netherlands, Ruben, Remco, and Sep believed the Elios 3 could gather the necessary data. They opted to use the Elios 3 for data collection, as its LiDAR payload would enable more precise identification of defects and anomalies during processing. In collaboration with NS Stations and ProRail, they planned to use a LiDAR scanner on the ground to map out the building structure and cable locations, ensuring safe drone flight planning. European regulations strictly prohibit flying drones near people or crowds, so this step was essential.

Initially, they intended to conduct the inspection with trains still operational. However, flying directly over trains is prohibited. Thus, they decided to perform the inspection flights at night when there would be fewer trains and fewer people around. Additionally, since they were operating within the control zone of a nearby major airport, they coordinated with Air Traffic Control during their drone flights.

Results: Nighttime Flight with the Elios 3

After meticulously mapping the space between the roof, cables, and metal beams using LiDAR, Ruben began scouting the area with his Elios 2 drone.

The Elios 3 drone flew around the station at night to gather data - can you spot it in the photo?

Following the initial reconnaissance, Ruben returned on a different day with the Elios 3. He followed a pre-planned route, focusing on areas of particular concern to the station managers while also conducting a general assessment. A construction advisor was present on-site to guide optimal data collection by highlighting key areas of interest.

The only challenge was ensuring no flights coincided with trains passing through the station. The team arranged for two observers on the platform to communicate via radio with Ruben, warning him of incoming trains to prevent any conflicts.

Advantages of the Elios 3 Drone for Infrastructure Inspections

In the past, such inspections required scaffolding and the closure of three train lines for maintenance, deactivation of the catenary voltage, and approval obtained weeks in advance. This traditional approach is far slower, lacking real-time data for proactive planning and offering limited situational awareness. Regular inspections are scheduled every ten years to preemptively address potential issues rather than reacting as needed.

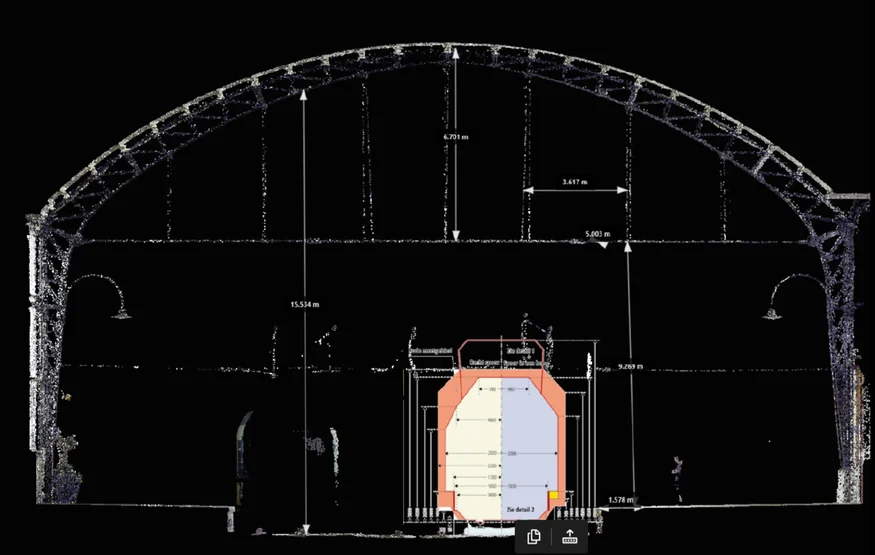

The entire building structure could be visualized using the LiDAR point cloud, complete with distance measurements

Risks were significantly minimized by utilizing the drone. Accessing the roof manually is hazardous due to the risk of electrocution from the catenary and collisions with moving trains. Furthermore, the drone's built-in lighting system, emitting 16,000 lumens, ensured excellent visibility despite the nighttime operations. Its adaptability and ability to navigate confined and complex spaces made it the perfect tool for this project.

The Elios 3 in Future Railway Infrastructure Inspections

Both Vortex and NS Stations were already familiar with drone inspections, even making headlines in the Netherlands for their previous drone-based work. This latest project has taken station management to a new level of detail. It provided unprecedented situational awareness and site knowledge while keeping employees and passengers safe.

When maintenance isn’t feasible, a complete station renovation requires planning two years in advance. However, this time, only the necessary repairs were carried out without halting or drastically reducing the station's operations. Besides the safety advantages, significant cost savings—amounting to millions of euros—are achieved by avoiding full renovations and saving time through accurate site data for planned maintenance.

The Elios 3 saved weeks of work, eliminated unnecessary high-altitude tasks, and kept rail traffic uninterrupted

ProRail, the client for this platform roofing project, stated, "Using the Elios 3 for inspecting roofs above train tracks and platforms is a fantastic alternative to conventional visual inspections. The use of drones allows greater flexibility, as scaffolding is no longer required before conducting inspections. This saves substantial time and reduces inconvenience for travelers while minimizing train downtime. Moreover, it enables more targeted asset assessments."

With this workflow, railway station managers can adopt a proactive approach to maintenance rather than adhering to rigid schedules based on estimated asset conditions. Thanks to the Elios 3 drone, they can now visualize the entire structure in 3D from their computer screens.

Learn more about the Elios 3 and its diverse applications.

Nantong Zhongyi Electronic Technology Co., Ltd. , https://www.apl-pickleball.com