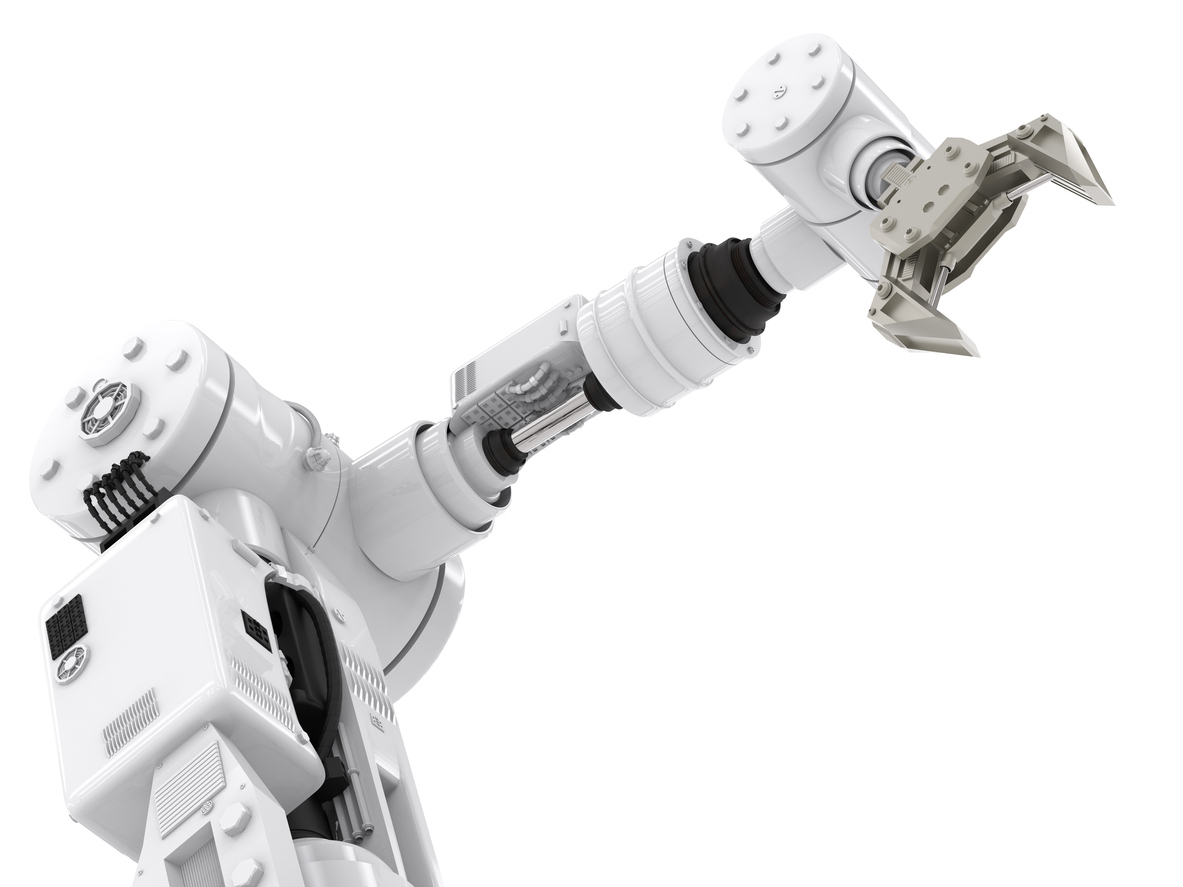

Industrial robots have become a game-changer in machine tending applications, offering manufacturers a powerful way to reduce cycle times and boost overall efficiency. Unlike manual operations, robotic systems can perform repetitive tasks with speed, precision, and consistency, leading to significant improvements in productivity and cost savings. One of the most compelling reasons to adopt robotic machine tending is the ability to maintain high throughput while minimizing downtime. With advanced automation, machines can be tended continuously without human intervention, which not only reduces labor costs but also increases output capacity. This makes robotic solutions an attractive investment for businesses looking to stay competitive in today’s fast-paced manufacturing environment. To ensure long-term success and return on investment (ROI), robotic machine tending systems must meet specific performance criteria. These include: By integrating these essential features, manufacturers can achieve substantial gains in efficiency and profitability through robotic machine tending. A real-world example of the benefits of robotic machine tending comes from a case study by Genesis Systems Group. An agricultural manufacturer producing drive train components faced challenges with manual tending, including long cycle times and inconsistent results. They needed an automated solution that could handle 16 different part numbers with minimal operator involvement. The solution involved a single-robot work cell equipped with dual 3-jaw grippers, a 180-degree indexing system, a 2D vision system, and red LED lighting. This setup allowed the robot to accurately identify and handle various parts, significantly reducing the cycle time to under 60 seconds per operation. The system maintained an impressive 95% uptime, proving its reliability and effectiveness. As a result, the manufacturer was able to eliminate inefficiencies, improve product quality, and achieve a strong return on investment. This case demonstrates how robotics can transform traditional manufacturing processes into more efficient, scalable, and profitable operations. If you're interested in learning more about this success story, you can read the full case study by Genesis Systems Group. It offers valuable insights into how robotic machine tending can be implemented to achieve measurable results in your own facility. Yutian Jifu Paper Products Co., Ltd. , https://www.yutianjifu.comReducing Cycle Time for Machine Tending with Industrial Robots

Key Features of a Successful Robotic Machine Tending System

Case Study: Agricultural Manufacturer Cuts Cycle Time with Robotics