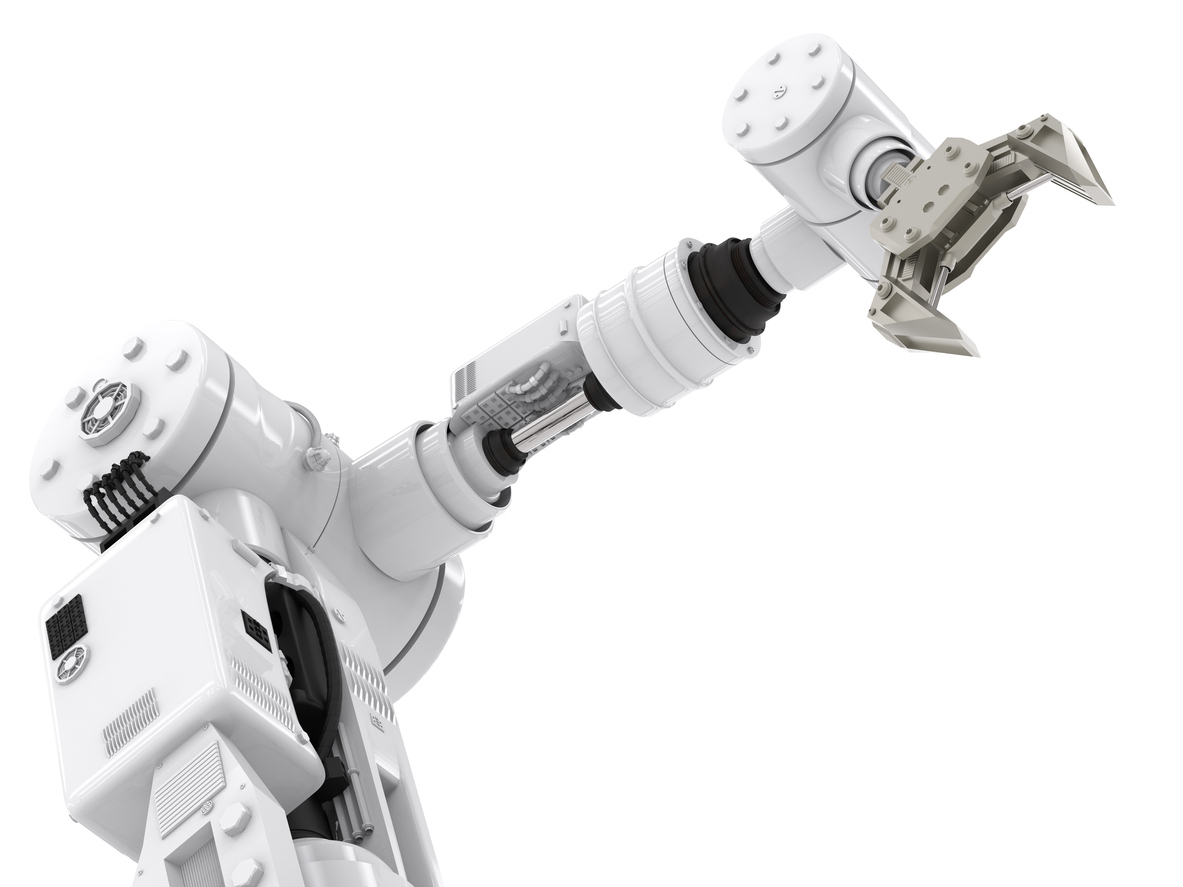

Industrial robots have become a game-changer in machine tending applications, offering manufacturers the ability to significantly reduce cycle times and boost overall productivity. Compared to traditional manual methods, robotic systems bring speed, precision, and consistency that can transform production efficiency. When implemented effectively, robotic machine tending not only improves operational performance but also delivers a strong return on investment (ROI). The key is ensuring that the system is optimized to handle the specific demands of the application, from part handling to tool changeovers and integration with existing machinery. To ensure long-term success and ROI, industrial robots used in machine tending must meet several critical performance criteria. These include: By integrating these features, manufacturers can achieve consistent, high-quality output while reducing labor costs and increasing production rates. A real-world example of this transformation comes from an agricultural manufacturer specializing in drive train components. Facing challenges with manual machine tending, the company partnered with Genesis Systems Group to implement an automated solution. The project involved automating 16 different part numbers with minimal operator intervention. A single robot work cell was set up using dual 3-jaw grippers, a 180-degree indexing system, a 2D vision system, and red LED lighting to ensure accurate part identification and handling. The results were impressive. The overall cycle time was reduced to under 60 seconds, and the system maintained an impressive 95% uptime. This allowed the manufacturer to eliminate inefficiencies, improve product quality, and achieve a strong ROI. This case study highlights how robotic machine tending can be a powerful tool for manufacturers looking to enhance productivity and stay competitive in today’s fast-paced industrial landscape. For more insights into how robotics can transform your production line, explore the full case study by Genesis Systems Group. Yutian Jifu Paper Products Co., Ltd. , https://www.yutianjifu.comReducing Cycle Time for Machine Tending with Industrial Robots

Key Features of an Effective Robotic Machine Tending System

Case Study: Agricultural Manufacturer Cuts Cycle Time with Robotics